AUTOMATIC STONE MILL

Since the ancient times, men utilize stones to grind cereals. In the course of the years new technology has improved the Mill’s frames in order to increase their efficiency and the grinded product quality looking for simple and cheap maintenance, but the grinding stone has remained the same. Today modern nourishment science has rediscovered the high value of Wholemeal Flours produced with Stone Grinding Mills, in fact they preserve all the vitamins and salts, so as they are inside the grain. Rural millers, bakeries, milling industries and agriculture utilize our Stone Mills, especially for Wholemeal Flour products. These Mills can only grind dry products and not oily ones. Stones are hard, wear and tear proof and produce soft, light not overheated flours.

RANGEE OF GRINDING PRODUCTS:

CEREALS: Wheat, Maize, Barley, Millet, Rice, etc.

LEGUMINOSEA: Broad-beans Lentils etc.

SPICES: Pepper Paprika Salt etc.

CONSTRUCTION DETAILS:

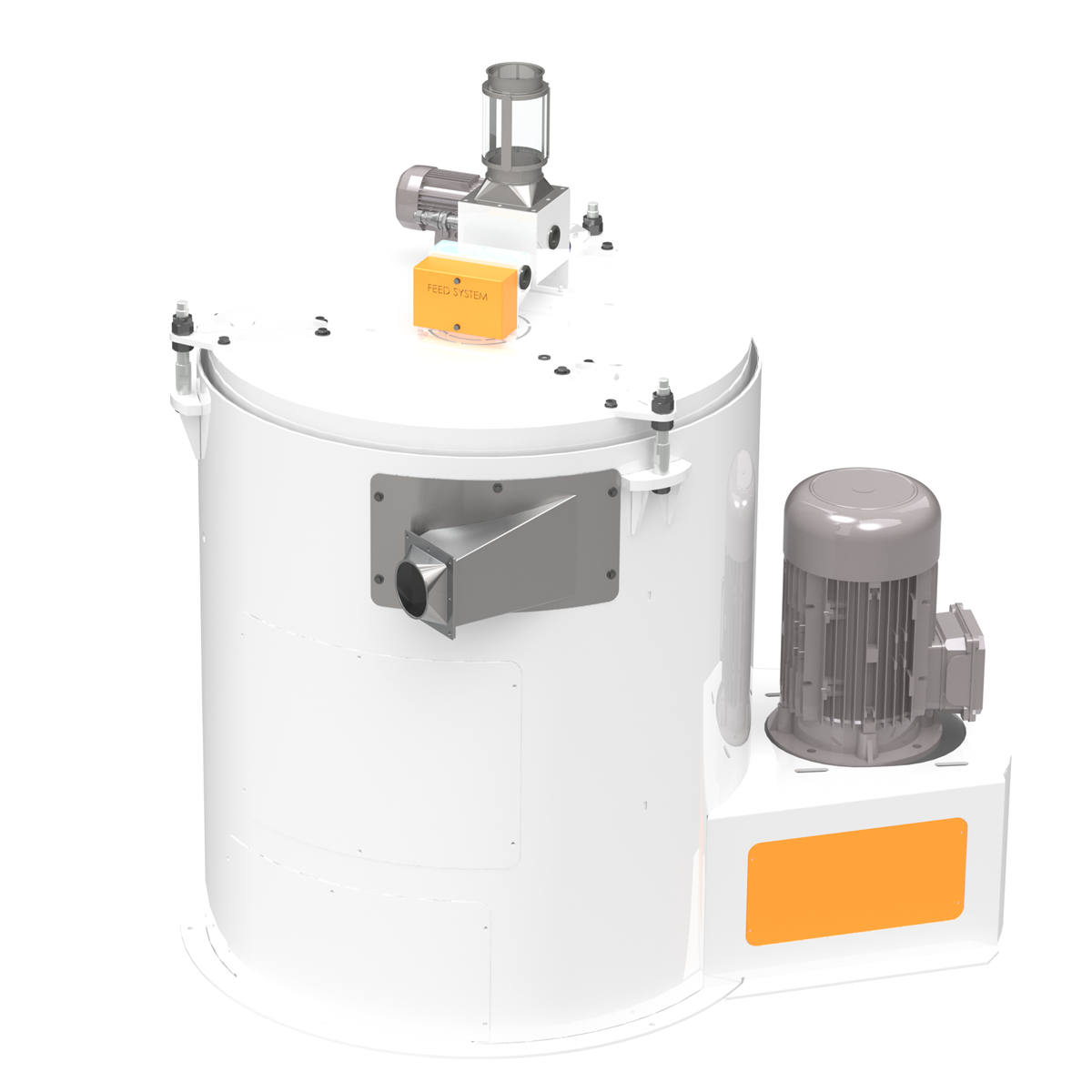

Our Stone Grinding Mill mod. EPO-M1000A is equipped with strong stones whose diameter is 1000 mm. The stones are made only of natural materials agglomerated by magnesite, they are very solid and have excellent resistance to wear; unlike the classic monolithic stones, our ones do not need to be dressed, do not require maintenance and a have a very long duration. Mill mod. EPO-M1000A has been projected to be proposed to customers requiring high level of output and quality; indeed, it is completely built in carbon steel sheet, in such a way to avoid any possible deformation or vibration, cause by frame’s flexibility. All the metal parts of the Mill are furnace painted with dust finishing varnishing and are approved to be used with human food products. The double screw feeding system, that grants a great precision in the regulation of the product flow that is about to enter in the grinding chamber, is equipped with visual alarm and a minimum level probe to control the presence of the product in the feeding. The fineness degree is electronically regulated by a gear motor with reduced backlash that, with a micrometric movement, makes the stones closer or more separate in order to obtain the desired flour. The upper stone is fixed, while the lower one rotates by means of a strong transmission shaft, mounted on two dust proof bearings, put inside one bearing house, that makes the whole stronger and avoids any possible shaft maladjustment.

TECNICAL DATA TABLE

| MODEL | POWER (kW) |

NOMINAL CAPACITY (kg/h) |

LENGTH (mm) |

WIDTH (mm) |

WEIGHT (kg) |

|---|---|---|---|---|---|

| EPO-M1000 | 18,5 | 400 kg/h | 1650 | 1350 | 1250 |