SIFTERS

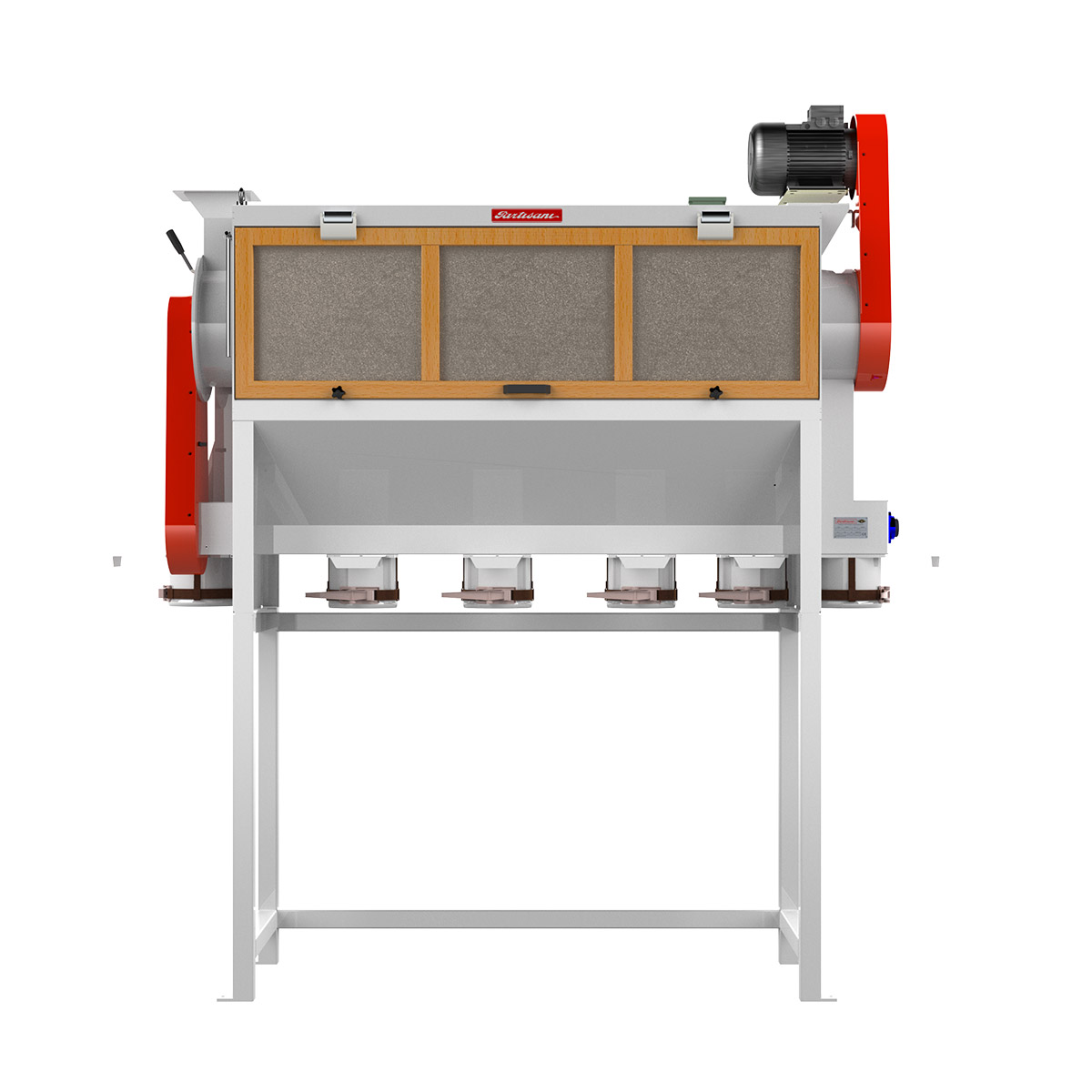

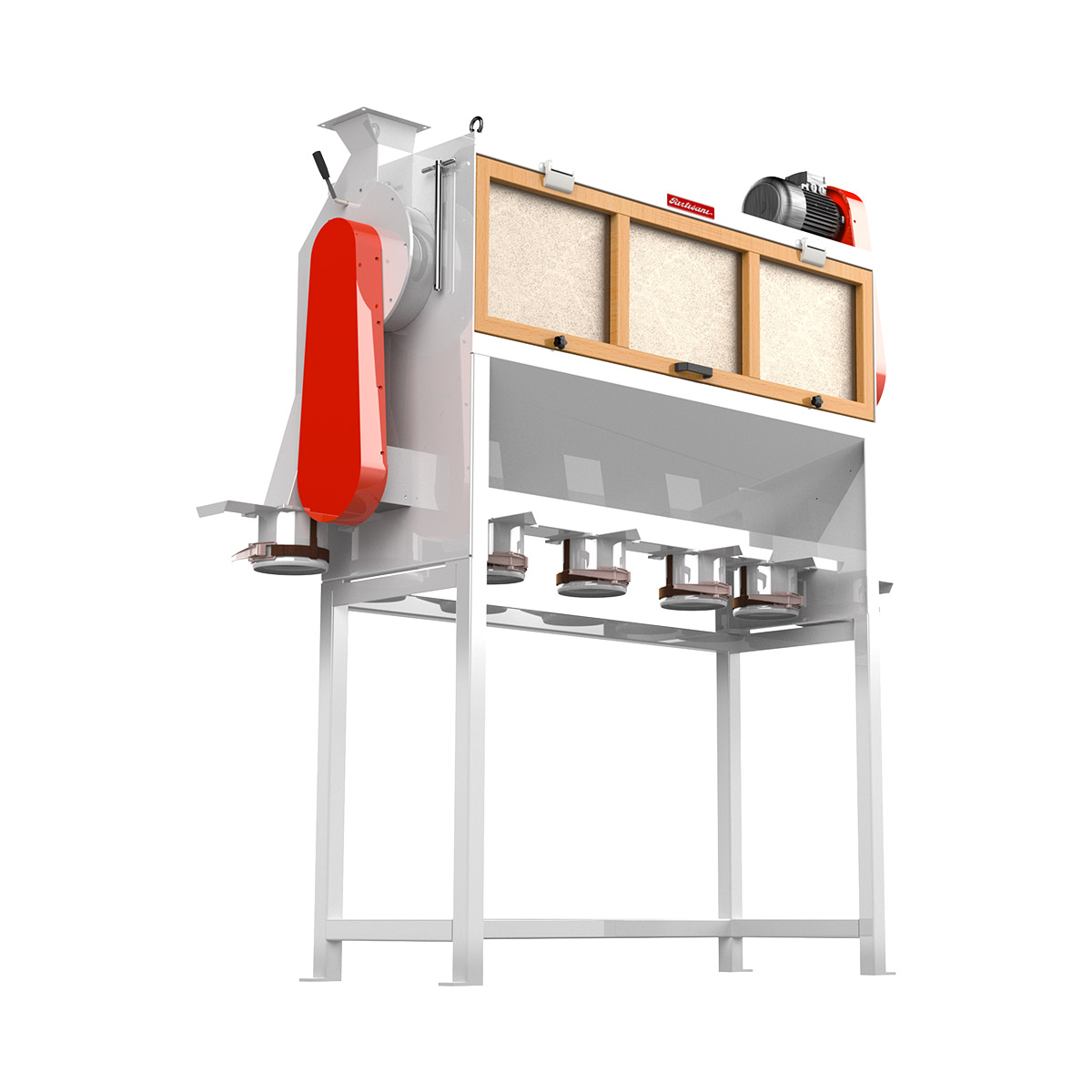

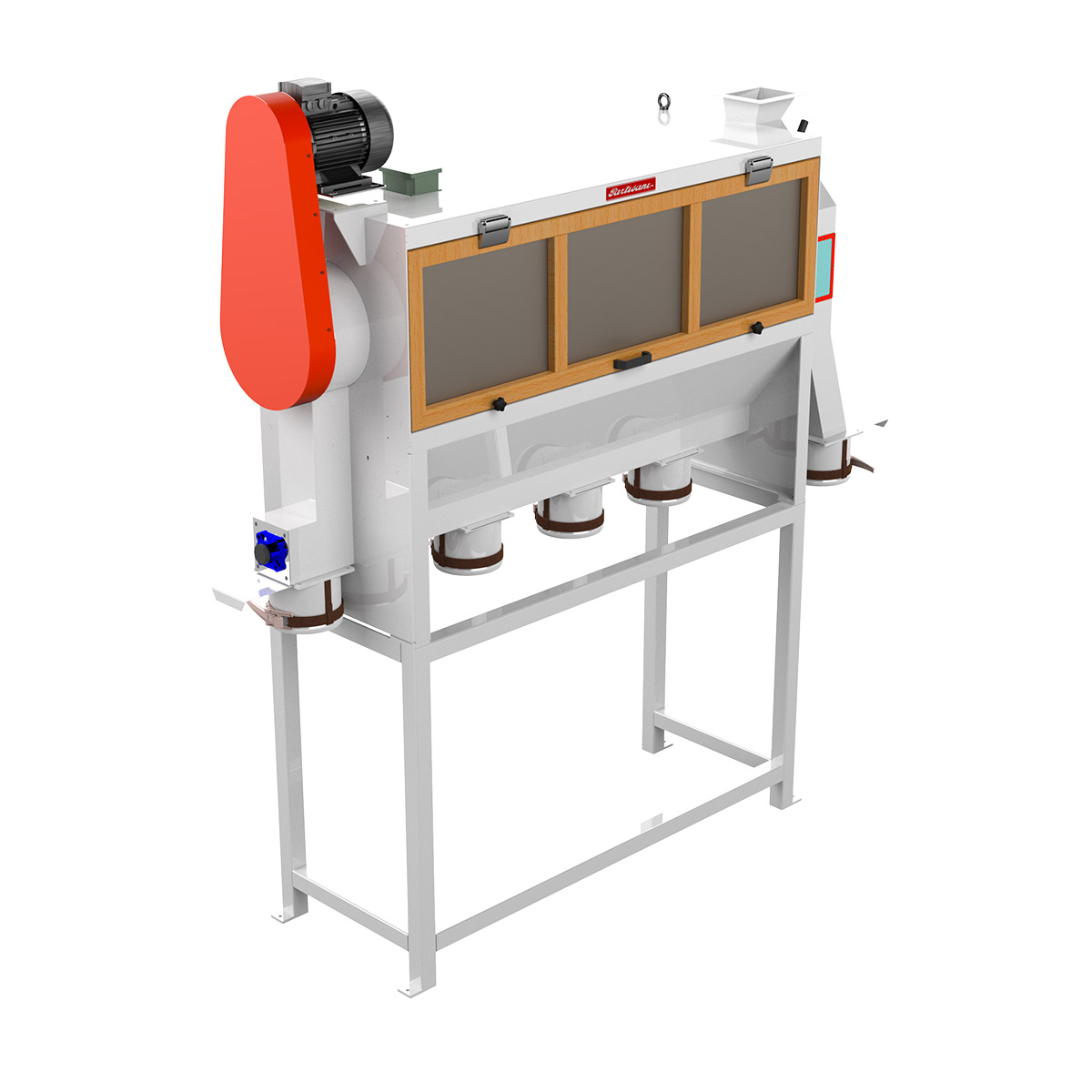

Our centrifugal vibration Sifter may be considered the ideal completion for our production of Stone Mills, in case you want to sieve whole-meal flour. It allows to obtain a high output with a high percentage of extraction. A minimum motive power absorption is required. Our Sifter has very small overall dimensions and it works efficiently and simply. Differently from the Plan Sichter, our Sifter combines the great flexibility of the flow diagram with the very simple and quick interchangeability of sieves. It allows to select various types of flours, bran and soft bran. A screw conveyor, placed in the lower part of the Sifter, collects the products and carries them to the outlets.

CONSTRUCTION DETAILS:

The whole structure is made of welded steel and it is furnace painted with non-toxic and food approved contact paints. A rotor operating by centrifugal stainless steel pulsation is set up on ball dust-proof bearings. The sieves are made of engineering food approved plastic and stainless steel. It consists of 3 or 4 separated discharge outlet for bagging the different types of flour and one lateral

outlet for bagging bran; in 300 and 350 versions you can bag the whole-meal product avoiding its

passage through the sifting chamber. Every discharge outlet is equipped with nozzles and leather lacers. It is driven by electric motor, complete with pulley and “V” belt inserted in strong protection cases. It is equipped with safety devices for impeding the operating when the doors are open.

TECNICAL DATA TABLE

| MODEL | SIFTING SURFACE (m²) |

CAPACITY (kg/h) |

SELECTIONS | LENGTH (mm) |

WIDTH (mm) |

HEIGHT (mm) |

POWER (kW) |

WEIGHT (kg) |

|---|---|---|---|---|---|---|---|---|

| BD200 | 0,7 | 200 | Up to 4 | 1500 | 550 | 1870 ÷ 2170 | 0,75 | 150 |

| BD300 | 1,3 | 350 | Up to 4 + 100% wholemeal bypass |

1900 | 800 | 2175 ÷ 2475 | 1,5 | 300 |

| BD350 | 1,9 | 800 | Up to 5 + 100% wholemeal bypass |

2300 | 800 | 2305÷ 2605 | 2,2 | 350 |