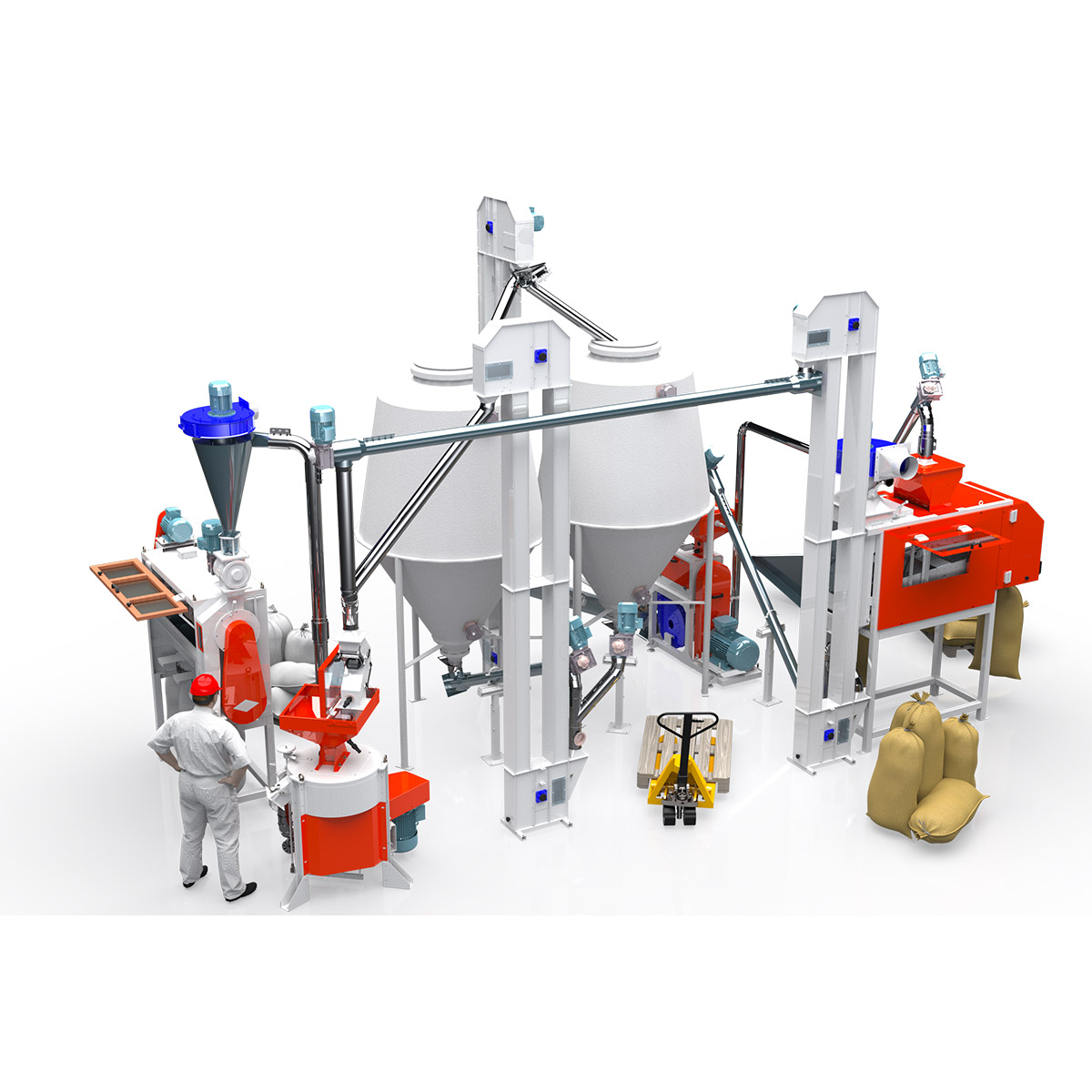

95i10-PDB

It is normally realized with capacities ranging from 300 to 800 Kg/h, it is obviously the most complete of our standard lines and the one that is most suitable for customizations and extensions.

Particularly appreciated by those who have medium high production needs, this series of plants in fact, in addition to grinding and sifting cereals, have a whole series of pre-milling processes such as, Cleaning, polishing and wetting in search of maximum consistency in the quality of the flours obtained.

The cereal is placed directly or by means of a loading screw, in the hopper of the cleaner that eliminates impurities and powders, then the cereal is sent to a polisher that thanks to its abrasive action on the grains completes the cleaning, the husked grain is unloaded directly into the grain damper, which moistens it and then sends it to a resting silo. An extraction screw picks up the grain from the silo and sends it to the Stone Mill, which, thanks to the Pneumatic Transport, keeps operating temperatures low and prevents dust formation in the environment, send it to the centrifugal sifter separating the cortical parts from the flour.